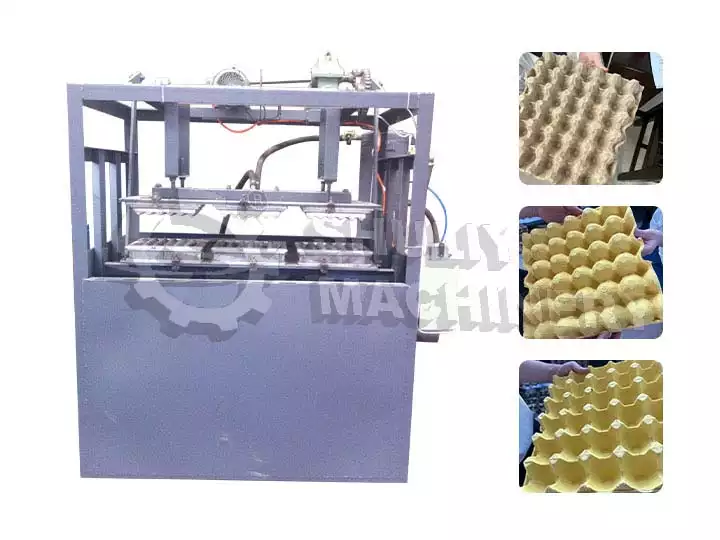

Shipment of 1500pcs/h egg tray machine to Nepal

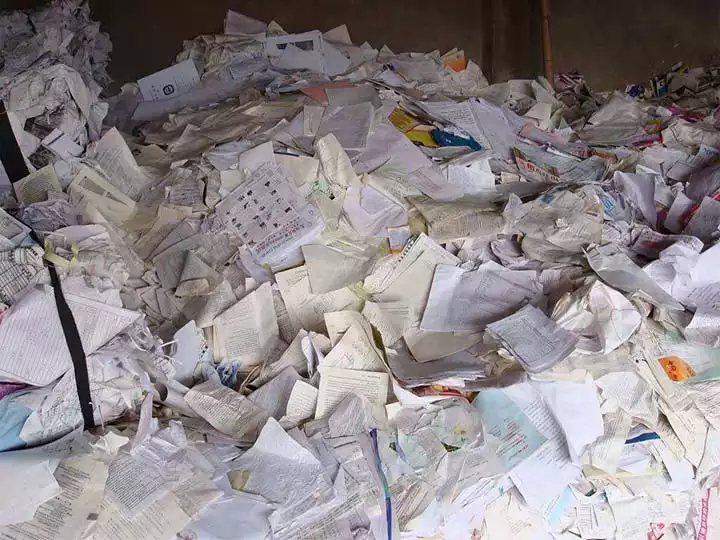

The Nepalese client has been engaged in the recycling business of waste materials for a long time and has accumulated rich market experience. In the process of recycling waste paper, he found that there is a growing demand for environmentally friendly packaging materials in the local market, especially egg tray products.

After an in-depth study of the market, the client decided to use the recycled waste paper to further extend the industrial chain and produce egg trays on its own, in order to improve the utilization value of waste paper and increase the source of income.

The client plans to start egg tray production with an initial target of 30 egg trays per day and gradually expand the scale.

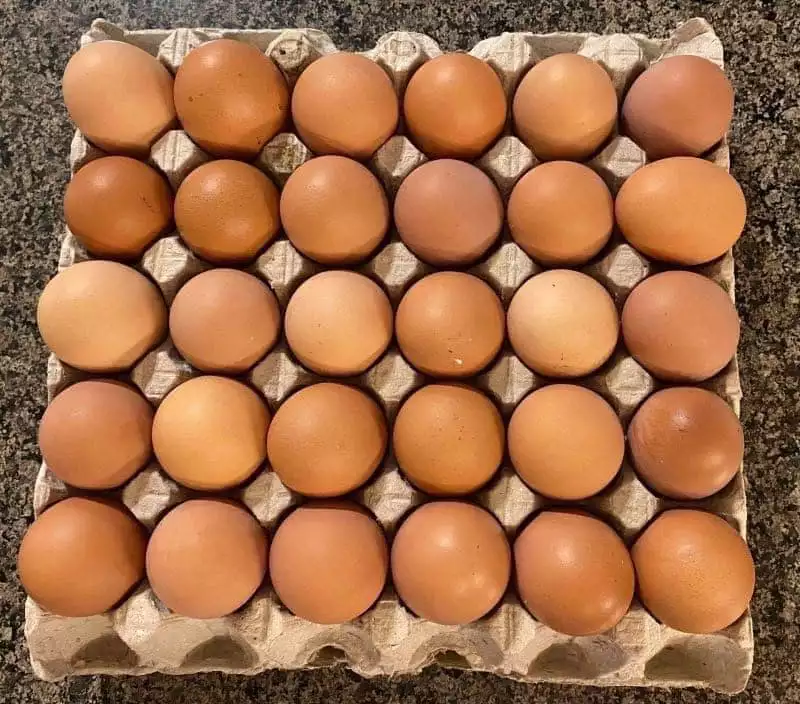

Why choose to produce 30-pack egg trays?

The customer’s target market is mainly local farmers and egg wholesalers, who need a stable supply of high-quality egg trays to protect their eggs. After market analysis, the customer found that 30pcs egg trays are the most popular size in the market, with high demand and easy transportation and storage. Therefore, he decided to invest in an egg tray machine to meet the market demand.

Reasons of choosing our egg tray machine

After comparing several suppliers, the customer finally chose our egg tray forming machine for the following main reasons:

- Mature technology: our egg tray machine adopts advanced molds and molding technology to ensure that the egg trays produced are strong and durable.

- Environmental protection and energy saving: using waste paper as raw material reduces the waste of resources and is in line with the concept of environmental protection.

- High degree of automation: the customer chose SL-4*1 paper tray machine with high production efficiency, which can produce 1500 pieces of egg trays per hour, fully meeting his market demand.

- Perfect after-sales service: we provide a full range of technical support, including installation guidance, operation training and remote technical support, to ensure that the customer can carry out production smoothly.

Implementation effect

After the equipment is put into production, the customer can produce 30 egg trays per day stably, and the production efficiency fully meets the expectation.

By using recycled waste paper as raw material, the customer successfully combined environmental protection recycling with egg tray production, realizing the efficient use of resources. Also, the project has gained good social repercussions in the local community and enhanced the customer’s brand image.